Additional Services

Pin Recoil LugBolt Handle Skeletonizing

Bushing Striker Pin Hole

Clip Slotting For M40 Style Optic Base

LRI Side Bolt Release

AIAW Magazine Well Modification

AR-15 Extractor

NOTE: Gunsmithing Services are invasive and will most often (directly with tooling or indirectly with work holding) damage existing surface finishes on parts such as receivers. LRI offers a full menu of finish options for your components, please ensure you have also added an appropriate finish option to your cart if applicable.

Finish Options

Cerakote (most popular)Parkerize Carbon Steel Action

Parkerize Carbon Steel Bolt

Glass Bead Stainless

GUNSMITHING SERVICES: Receiver Blueprinting

Blueprinting, or "truing an action" is a machining process meant to improve the accuracy potential of a factory bolt action rifle. While we still follow the spirit of this process, we've grown the process to also improve the overall functionality along with a menu of optional features.

A lot of this has nothing to do with making the rifle "more accurate." Instead, it checks boxes regarding detail work overlooked by the OEM and competitors to ensure your piece functions above expectation.

LRI pioneered the use of CNC Vertical Machining Centers to blueprint bolt action receivers starting in 2009. From a very humble beginning, we've continually refined and improved the process to where our work can stand right along with many of the custom aftermarket receivers made today.

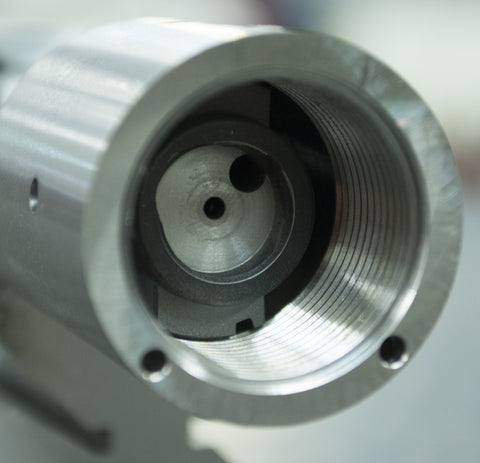

In 2013 we introduced another industry exclusive; Single stroke diamond-honed receiver bores using a Sunnen connecting rod hone fitted with custom-made tooling. Honing ensures the receiver bore is round, taper-free, and void of inclusions. It also provides a qualified surface for the setup process in the milling center.

The final chapter to all of this was in 2019 with the implementation of a cutting-edge 5-axis receiver and bolt blueprinting process. No other custom gun shop anywhere has this resource.

Haas UMC750 5-axis machining center

M700 workholding:

Finished receivers, M700

M70 workholding:

Winchester Model 70:

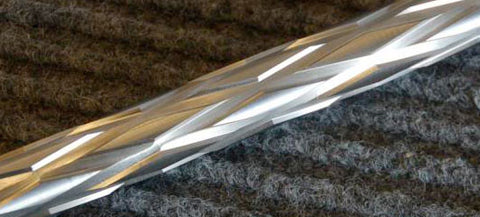

The receiver work is but one part of this effort. Bolt work is also a fully automated process using wireless probing routines and automated programs. In addition to the fundamental blueprinting service, we can also add several custom options; Striker pin bushings, altered bolt face diameters, M16 (and "mini 16") extractors with dual ejectors, fluting, skeletonized handles, faceted bolt shrouds, and our Time&TIG service.

LRI makes its M16 extractors in-house. We do this to ensure a clean installation and to standardize the process. Our extractors are billet machined from 4140 Chromoly steel and heat-treated/tempered.

LRI Std M16 Extractor and Dual Ejector upgrade:

LRI Billet steel M16 Extractor:

Detail of M16 extractor machine work to M700 bolt:

LRI Mini M16 Extractor upgrade:

The result is features and a level of precision that were once the exclusive domain of custom actions.

Remington M700 Tier 1 Blueprinting Standardized Features:

- Single Stroke Diamond Honed ID receiver bore

- Higbee thread lead on receiver ring threads

- Receiver ring ID bored

- Thread milled receiver ring threads

- Reconditioned Receiver Lug Abutments

- Bolt nose resurfaced

- Bolt face resurfaced

- Bolt Lugs resurfaced

Remington M700 Tier 2 Blueprinting Standardized Features:

Retains OEM threads, used for Savage-type barrel nuts or "Remage" setups or for prefitted barrels.

- Single Stroke Diamond Honed ID receiver bore

- Reconditioned Receiver Lug Abutments

- Bolt nose resurfaced

- Bolt face resurfaced

- Bolt Lugs resurfaced

Optional Features and Services: (Both Remington Tier 1 & 2)

- Striker pin Bushing installation

- Time and TIG bolt handle

- Turn Striker Pin to .0625"

- Std M16 Extractor installation

- Mini M16 Extractor installation (.223 bolt face only)

- Dual ejector upgrade

- Clip Slotting receiver for M40 style lugged optic base

- LRI External side bolt release installation

- Pinned Recoil lug (limited to LRI lugs only)

- Wide variety of bolt fluting options

- Jeweled bolt body

- 8-40 optic base hole enlargement

- Fluted Bolt shrouds

- Skeletonized bolt handle

- Extended internal magazine modification

- AIAW magazine modification to the receiver

- Filling tang groove on M700 SS actions via TIG-welded silicon bronze

- Tactical bolt knob installation

- Single and multi-colored Cerakote application

- Parkerize coating application (limited to carbon steel actions only)

- Glass bead blast finish (limited to stainless actions only)

- Installation of aftermarket bolt handle

- Fitting aftermarket bolt to receiver

- Reconditioning factory recoil lug (ID bored and surface grinding both sides)

Winchester M70 Tier 1 Blueprinting Standard Features:

- Single Stroke Diamond Honed ID receiver bore

- Receiver ring face machined

- Recessed forward lug face

- 2.5* draft angle on the forward side of the lug, 4* side drafts, and .100" corner radiuses avoid tearing up bedding when the receiver is removed from the stock.

- Thread rings opened up to 1-1/16-18 threads per inch. Adding circumference and increasing the thread pitch adds surface area to the threaded joint - a perfect complement to M70's short tenon length.

- Truncated "Higbee" thread start

- Faced lug abutments

- All machined features either have chamfers or edge breaks

- Fully CNC machined in a single setup using true 5-axis machining capabilities.

- Conservative tool package greatly reduces tolerance stacking.

Winchester M70 Optional Features and Services:

- Striker pin Bushing installation

- Turn Striker Pin to .0625"

- Wide variety of bolt fluting options (CRF actions excluded)

- Jeweled bolt body

- 8-40 optic base hole enlargement

- Extended internal magazine modification

- Tactical bolt knob installation

- Single and multi-colored Cerakote application

- Parkerize coating application (limited to carbon steel actions only)

- Glass bead blast finish (limited to stainless actions only)

- Installation of an aftermarket bolt handle

M70 Receivers Currently Supported:

Winchester Pre-64 Model 70's, all years in both CRF and pushfeed configuration.

M70 Blueprinting Process - IMPORTANT:

Winchester M70 receivers are a casting, this presents a unique challenge because clamping the action in the required manner causes the receiver to distort due to the irregular exterior. Part of our process is to "deck" the bottom of the action so that it is flat. Because of this, any finish on the bottom of the receiver is machined away. This makes carbon steel actions more vulnerable to corrosion.

M70 Receiver ring threads:

The threads on the M70s in the controlled round feed and push feed configurations are 1-16. One inch diameter, 16 threads per inch. The historical process of "cleaning" up existing threads on M70s as part of blueprinting takes a radical turn here at LRI.

The major diameter of the existing one-inch thread becomes the minor diameter when we enlarge them to 1.0625"-18. We do this because the M70 threaded barrel cylinder is quite short. What we are after is increased surface area to better support the barrel in the receiver. There's no consequence because the receiver ring diameter is 1.350". -The same as the vast majority of other action designs. The other advantage here is we are effectively waving a magic wand over the action by working with virgin material. In the same setup, we also project the receiver ring face .05" and create a draft angle to the forward-facing surface of the recoil lug. This makes removal from a bedded rifle stock much easier and greatly reduces the risk of the action damaging the bedding material.

Proven Performance:

In the spring of 2013, LRI announced a very ambitious project to one of the toughest and most demanding precision rifle audiences in today's shooting community: SnipersHide.com

We began offering accurized M700 barreled actions through an internet special. Since that time LRI's "Sniper's Hide M700 Accurized Barreled Action Group Buy" has grown into the largest and most continuous internet special in the history of the Sniper's Hide website.

LRI has produced thousands of custom-built barreled actions for precision shooting enthusiasts. Our services have expanded to clients from all over the world. The success of the effort has ushered a new chapter in how precision bolt action barreled actions are assembled.

You are in good hands.

5-axis Blueprinting the M700:

IMPORTANT:

Finish Limitations with bolts and receivers.

The work LRI performs when blueprinting an action is invasive and extensive. TIG welding/soldering involves the careful use of intensive heat. Coatings applied to the bolt must be removed to avoid contamination of the welded/soldered joint.

Because of this, your bolt will require refinishing. This cannot be avoided. LRI offers a full menu of finishing options to restore your bolt to pristine condition.

Dimensional limitations with receivers and bolts.

It is very common for LRI to rework an action that has been previously blueprinted by another shop. We are very comfortable with this in almost all circumstances, but there are limitations.

Our blueprinting process allows us to preserve the OEM dimension of 1.150" measured from the receiver ring face to the top of the lug abutments on M700 actions. With "unmolested" receivers this is no problem. Receivers that have had previous work may or may not allow for this. It is a case-by-case basis as it all depends on how much material was previously removed.

This can add to the cost as it may require custom program editing.

A fundamental of any machining operation is rigid and solid work holding, (clamping the part to the machine in a manner that prevents it from unintended movement).

LRI treats your property with great respect, however, there are limitations. We cannot guarantee that our fixtures will not damage the surface finish of your receiver. We are as careful as we can be, but collets and vices are made from tool-grade, heat-treated steels. They are hard and very tough to ensure a repeatable register for thousands of cycles.

Because of this, your receiver may require refinishing. This cannot be avoided. LRI offers a full menu of finishing options that will restore your receiver to pristine condition.

Recoil lugs.

Our Tier 1 blueprinting service alters the factory M700 thread dimensions. They are enlarged to a value of 1.085"x16tpi. A factory/aftermarket recoil lug cannot be reinstalled without modification. We must ID bore the hole through the lug for the larger barrel tenon to fit through. This must be done when clients choose to use OEM or outsourced components. LRI also surface grinds all factory M700 lugs to bring the two sides to perfect parallelism. LRI recoil lugs are made this way from the start for a "drop-in" installation.

LRI limits the recoil lug pinning option to LRI-brand lugs only. Our recoil lugs come standard with pin bores drilled/reamed during manufacturing. The market is saturated with a variety of aftermarket recoil lugs. Attempting to fixture and archive tool paths for every recoil lug variation in circulation just isn't realistic.

We offer our lugs in Chromoly, stainless, and 6AL-4V Titanium and finished to a nominal thickness of .250" to fit in chassis-type stocks without alteration.

We Also Recommend