GUNSMITHING SERVICES: Muzzle Threading AND Crowning service

The incredible surge in the popularity of suppressors makes a threaded muzzle almost standard equipment on today's precision rifle. LRI is well-equipped for this extremely popular upgrade. With our resources and experience, your device will attach trouble-free every time.

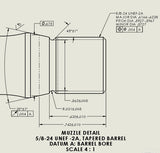

Muzzle threads for devices like suppressors and brakes are qualified using traceable, certified hard chromed ring gauges or a precision thread pitch micrometer to ensure your accessories adapt without issue. As standard equipment, we fit these types of muzzles with an 11* target-style crown because carbon deposits faster on the face if machined for the recessed type. If you would like us not to recrown your barrel, that is no problem. Simply annotate the change on your sales receipt in the notes section.

LRI has been vetted and endorsed by ThunderBeast, SRT, and Mac Bros. for suppressor-related barrel work. Since we opened our doors, none of our clients has ever suffered a baffle strike on any muzzle device.

Lever, Break Action, and Falling Blocks:

These types of guns present a unique challenge to gunsmiths performing this service. The breach end of the barrel has the receiver attached in a manner that is either permanent or very difficult to remove. This normally requires one of two things: A lathe with a very, very short spindle bore or one with a huge inside diameter.

Because of this, very few shops can thread the barrel's muzzle. LRI has solved this problem by migrating the job to a 5-axis milling center. Doing so eliminates the complications of setting up the part through the spindle bore of the lathe. Electronic probing and creative programming position the bore "plumb" to the spindle and establish the center.

From here, it's simple. We contour the end of the barrel, relieve the bottom at the shoulder, and chamfer the lead where the threads will start. Then the cylinder portion is threaded using "single point thread milling." A tool shaped like a saw blade and ground to the shape of a thread form is loaded and winds down the outside of the cylinder like a spiral staircase. Very, very accurate threading can be done this way. We finish with an inspection to ensure they are within tolerance.

Important Notes:

First, LRI is not a suppressor manufacturer or retailer. You will have to consult with a dealer/manufacturer for specific product information. You need to know exactly what thread diameter and pitch your suppressor is. LRI does not profess to know the intimate details of every single suppressor made. When it comes to suppressors, the choice of threads used on the can is "the wild west" as there is no "standard."

You are responsible for knowing exactly what the thread specifications are for the device you want to use. This is very detail-oriented because it has to be. Ensure that you KNOW what the dimensions are.

The diameter, Pitch, and Class of Thread are what we need to know.

Limitations:

"Cans" are expensive, and anyone who owns one can identify with the administrative gauntlet one has to endure before taking possession. The last thing anyone here at LRI wants is to ruin your suppressor due to a machining/installation mistake.

The thread shoulder on the barrel that a suppressor squares up against is an important feature that should be respected for direct-mount type cans. LRI advocates for a minimum of .100" diameter increase over the major diameter of the threads.

Examples:

- 1/2-28 = .600" Shoulder Dia.

- 9/16-24 = .6625" Shoulder Dia.

- 5/8-24 = .725" Shoulder Dia.

- 3/4-24 = .850" Shoulder Dia.

- M18x1 = .810" Shoulder Dia.

- "CUSTOM" = +.100" Shoulder Dia. over Major Thread Outside Diameter.

We advise clients also to develop the habit of lubricating threads with a high-temperature copper-based anti-seize compound. -ESPECIALLY with semiautomatic rifles, as the heat generated from high volume, sustained shooting can weld the can to the muzzle!

For heavier varmint/tactical-type barrel contours, these values are essentially meaningless because the barrels are already significantly larger.

The slimmer sporter/hunting contour barrels are where the issue becomes very relevant. We do not keep records on every single sporter barrel contour available from every manufacturer. You will have to do some research on your end to ensure your barrel can be safely threaded for a suppressor at the finished length you request.

When using a Bartlein #3 contour sporter barrel as an example, the following would apply for approximate barrel lengths that meet the +.100" rule:

- 1/2-28 = 26" max finish length

- 9/16-24 = 24.25" max finish length

- 5/8-24 = 18" max finish length

- M18x1 = Cannot be used as the barrel will be shorter than the 16" minimum required by law for a non-SBR-type rifle.

"finish length" is defined as the length of the barrel as it would be sitting on a bench with no receiver attached to it. The measurement is from breech face to muzzle crown.

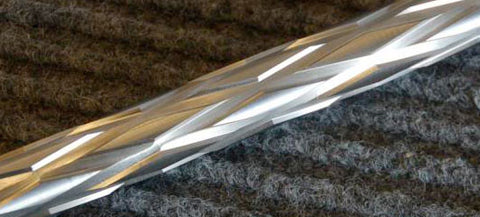

Last, the caliber and cartridge for a particular setup must be considered. As a general rule, LRI prefers a minimum of .100" wall thickness between the barrel groove diameter and the root diameter of the thread machined at the muzzle. This value does have some room for judgment. A 300-378 Weatherby Magnum is a powerful cartridge with muzzle pressures significantly higher than a 30-30 lever action the same barrel length. It would be acceptable to reduce the wall thickness for the smaller cartridge.

Our experience has shown that a thin wall muzzle has the potential to "bell mouth" over time. When a crown bell mouths, the rifle's accuracy suffers because the bore ID dimensions change. You, as the user, may be compelled to think the barrel "let go" due to throat erosion when it's actually because the muzzle was threaded with too thin of a wall thickness.

Please review these notes in detail and fully comprehend what is being explained. LRI performs this service based on the information we receive from you. We perform the work to established machining practice standards.

How it gets used is ultimately your decision and responsibility, not ours.

CURRENT LEAD TIMES: Subject to change without notice

- 5th Axis Muzzle Threading (i.e. Thompson Center, H&R, ANY Break action or specialty jobs that cannot fit in the lathe or cannot remove barrel): 3-5 weeks.

- There will be an additional $100 tear down fee on lever/break action rifles. This will be Invoiced upon completion.

- Any specialty/custom threads: 30 days

- Standard Muzzle Threads: 3-5 days

IMPORTANT NOTE: Muzzle threading is an invasive machining process that is very, very dependent upon solid and stable work holding. Failure to respect this fact leads to misaligned threads and possible damage to peripheral items such as suppressors or muzzle brakes. We have a well-vetted process for ensuring a visually clean appearance in our work. However, it is not without some cosmetic consequences. If your barrel is coated, blued, blasted, or "finished" in any way on the outside of it, it is very, very possible that we WILL scratch, burnish, or mark the finish.

There is absolutely no way to avoid this. Retaining this service means LRI will not accept or be subject to any liability in any capacity. Please consider this before retaining us for this kind of work.

We Also Recommend