NOTE: Gunsmithing Services are invasive and will most often (directly with tooling or indirectly with work holding) damage existing surface finishes on parts such as receivers. LRI offers a full menu of finish options for your components, please ensure you have also added an appropriate finish option to your cart if applicable.

Finish Options

Cerakote (most popular)Parkerize Carbon Steel Action

Parkerize Carbon Steel Bolt

Glass Bead Stainless

GUNSMITHING SERVICES: Detachable Bottom Metal Installation

LRI's reliance upon 3D computer generated tool paths provides for a neat, clean, and precise installation of a DBM system. Our unique process does not rely upon bedding the DBM into the stock. Instead we machine it 1:1 by taking advantage of powerful software and automation.

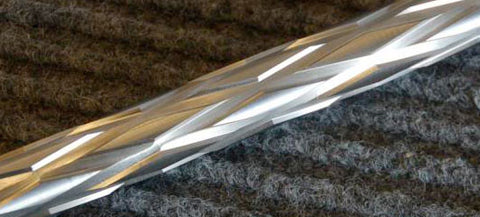

We've gone a step further with our "full installs" where we start with a virgin stock blank. LRI is able to mirror the profile of the floor metal to include the radius transition from magazine box to the trigger bow. This is done with what is known as surfacing tool paths. A tiny endmill machines the features by stepping over a little each time. It's a very, very "code intensive" process where thousands of blocks of cnc code are generated. The results make it worth it however.

Neat, clean, and distortion free. That is what we're after.

NOTES:

DBM installation is included with our Pillar Bedding or Surface Machined Inlet services.

We are able to install a DBM on Most aluminum chassis block style composite stocks as well. Manners, H/S, and Bell&Carlson are no problem. They do however have a couple limitations. The popular Surgeon DBM has a wider footprint than most others designed for the M700 action. This added girth results in the alloy chassis becoming very, very thin walled in the magazine well.

Experience has taught us that attempting to force the issue will almost always result in a ruined rifle stock. The aluminum becomes so thin it delaminates from the core material and fails.

For these reasons we will only install Surgeon DBM's in conventional composite and wood stocks with sufficient sidewall material. These are primarily designed to go into stocks like the Manner's T4, T5, and McMillan A-4, A-5 type stocks.

We Also Recommend