NOTE: Gunsmithing Services are invasive and will most often (directly with tooling or indirectly with work holding) damage existing surface finishes on parts such as receivers. LRI offers a full menu of finish options for your components, please ensure you have also added an appropriate finish option to your cart if applicable.

Finish Options

Cerakote (most popular)Parkerize Carbon Steel Action

Parkerize Carbon Steel Bolt

Glass Bead Stainless

GUNSMITHING SERVICES: Trijicon RMR Sight Installation

NOTE: This is a service only listing. Client is responsible to provide the pistol slide, sight, adapter plate (when applicable) and all required hardware.

Trijicon's RMR sight installation from LRI is performed on our new 5 axis cnc machining center. The use of wireless probing and extremely powerful CAD software allows us the ability to consolidate operations into a single setup.

The advantage of this for you is that the sight is placed at the perfect location and the ideal height for those wanting to retain the OEM iron blade type sights.

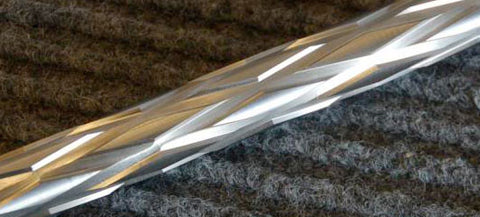

Glock pistols are known to be harder on tooling due to the "Tenifer" coating. We encountered this as well so to solve the problem, we began making our own dovetail cutters for blade sight relocation.

We offer the sight installations in a variety of configurations:

- Combat. (RMR sight installed behind the ejection port and in front of the OEM rear sight blade)

- Race #1. (RMR sight installed in its most rearward possible location which removes the OEM rear sight dovetail feature from the slide)

- Race #2. RMR sight installed the same as "Race #1" but with the dovetail feature relocated to sit between the ejection port and the RMR sight base.

Combat:

Race #1:

Race #2:

We also offer RMR installation to other pistols such as the Smith And Wesson SW1911TA. This involves the use of an adapter plate.

SW1911TA RMR conversion:

Information regarding additional options:

Since conception, LRI has made the conscious effort to be the most transparent and straight forward custom gun service center in existence.

Pistol work is new to us and no one here makes any claim to being an expert in regards to application or part selection. You as the client MUST do your homework and know exactly what it is your wanting because we simply do not have the experience or "tribal knowledge" to be of assistance.

What we are extremely good at is high caliber machine work using the most modern processes available to the custom firearms industry. This is where we shine and are able to help.

We are happy to take on new applications for these types of sights. Just know that when you call, YOU are directing the show. We'll handle the machine work, but you must know what your doing and be able to accurately articulate the project.

Happy to help.

CURRENT LEAD TIME: 4-6 MONTHS

We Also Recommend