NOTE: Gunsmithing Services are invasive and will most often (directly with tooling or indirectly with work holding) damage existing surface finishes on parts such as receivers. LRI offers a full menu of finish options for your components, please ensure you have also added an appropriate finish option to your cart if applicable.

Finish Options

Cerakote (most popular)Parkerize Carbon Steel Action

Parkerize Carbon Steel Bolt

Glass Bead Stainless

GUNSMITHING SERVICES: AR-15/M-16 Extractor installation

The AR-15 /M-16 extractor upgrade for an M700 bolt is a very popular and almost required service for several applications. When working with magnum bolt face cartridges, the AR-15/M-16 extractor is almost a must-have as the riveted factory piece is prone to be problematic.

The AR-15/M-16 Extractor service applies to bolts for the following Remington actions: M700, M7, 40X, 788, 721, 722

Bergara actions: B14

The Dual Ejector modification is only applicable to the M700 (EXCLUDES OEM M700 IN 338 LAPUA), M7, 40X, 721, 722

NEW:

Starting in 2025 we can now upgrade a Winchester Model 70 Push Feed, Plunger Eject bolt to an M16 style extractor. This service is limited to ONLY this bolt design/legacy. The bolt was originally fitted with a "T slot" style extractor.

A close inspection of factory bolts reveals several intricately machined features where the factory extractor resides. These features can have a detrimental effect on the operation of an AR-15 extractor because the case rim tends to become impinged on the underhook feature that retains the OEM extractor spring.

Because of this, the first thing we do is fit a bushing to the bolt face. This is where the departure from the norm begins because our bushings are threaded directly into the nose of the bolt face. Using state-of-the-art CNC machining centers fitted with 3D electronic probing allows us to achieve this delicate process.

By knowing exactly where the part is, machining strategies can be implemented to deliver a true mechanical lock between the bolt body and the extractor bushing. Threading delivers a powerful means of mechanically locking the two parts together. The industry “norm” has been to rely on epoxy, which is very prone to failure. We rely upon low-temperature solder applied with magnetic induction to lock the thread in place. Solder delivers the strongest means of bonding the two parts together permanently so that the insert can never rotate inside the nose of the bolt.

The next phase involves facing the bushing flush with the existing nose of the bolt. Next, the ID is bored to a diameter appropriate for the intended cartridge size.*

*With our process, you are given a blank canvas. A 223 Remington bolt can be turned into a 300WSM without any concerns about reliability or function!

The bolt face is then resurfaced to ensure perpendicularity to the body axis, and edge break features are machined to enhance reliable function while also avoiding abuse on brass case rims from sharp edges.

This process also allows us to include additional details such as dual ejectors* for situations where the altered ejection angle can cause issues with large scope turrets. We can also install striker bushings* to address the issue of cratered primers.

*NOTE: These are optional services

This concludes the first operation. From here, the part would normally be transferred to a 2nd fixture where the inletting work is done. LRI further ushered this process into the modern age using true 5-axis machining! We are the industry leader in action blueprinting with this technology.

The bolt body is automatically positioned to the exact orientation for all follow-up operations. This means that Pinholes and pocket features unique to this service are accurately located and machined. The risk of tolerance stacking and work holding errors is eliminated because the part is physically positioned in one setup.

Wireless probing provides a predictable and reliable means of locating the part regardless of how it is presented to the tool in the spindle. As a standard practice, the face of the bolt will be surfaced slightly when installing the extractor. This removes any residual solder present after the bushing is installed. Your headspace will change between .0005" and .001". For reloaders, all that is required is a small adjustment of your sizer die setup. For shooters using factory ammunition, there is no change required.

We didn't stop there. Various companies are making the M16 type extractor for bolt action rifles. Within that community exists small yet important differences. None is better than the other. However, it does require one to be "on the ball" so that the appropriate program is loaded into the machine. This is a complication that leads to mistakes. Our solution; is we manufacture our extractors in-house.

The LRI M16 extractor is compatible with both .480 and .545 bolt face cartridges. .308 and Standard Magnum. We also offer a mini extractor for rifles chambered in 223, pictured below.

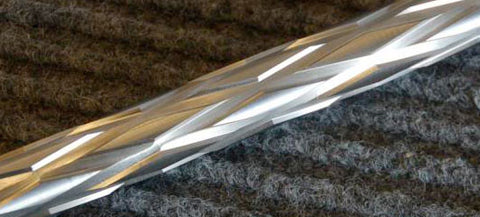

The extractors are 100% machined from tool-grade steel bar stock. NO sintered metal is used! The existing extractor design is quite good, so we didn't try to reinvent any wheels. That said, some small changes were made. The claw feature now has a .005" radius to mitigate abuse to the case rim.

The outside radius is 3D surface machined rather than contoured.

Once complete, they are shipped to an aerospace heat treatment facility in Seattle, WA. Seattle is noteworthy because of its heavy aerospace manufacturing presence. The high standards of that community ensure that you receive a reliable and predictable outcome from this product.

UPDATE: 6.1.2023

We can now retrofit Remington M700-type bolts with M16 extractors previously fitted with SAKO extractors! This is an LRI industry-exclusive service.

Notes* Over the years, there have been instances (very few, but they have happened) with extractor claw failures. The claw feature would break off from the extractor body. Efforts to mitigate the problem by altering the heat treatment (hardness level) were met with intermittent success.

In the summer of 2021, we decided to revise the design slightly by adding more material around the claw area of the extractor. Doing so resolved the failure issue by increasing the strength and durability of the claw feature. A consequence of this, however, is an issue specific to the magnum extractor installation.

Because the case rim diameter on a magnum cartridge is larger than a .308 diameter case, the extractor must pivot further away from the centerline by a small amount as it slips over the case rim to gain the required purchase. Because Remington-style barrel tennons use a counterbore feature on the breech face, the outer portion of the extractor is likely to interfere with the inner ring of the barrel as it attempts to slip over the cartridge case rim on the OEM inside diameter.

Determining this is easy as it's a "Pass/Fail" exercise. If the bolt fails to close on a loaded chamber after the installation of a magnum extractor, it's almost a certainty that the breech ring ID interference is the problem. Solving this problem requires the barrel to be removed from the action and the inner ring to be opened up slightly in a lathe with a boring bar. It's a very simple process for any vetted gunsmithing shop to perform.

LRI balances this small inconvenience against the increased reliability. We feel it's worth the effort as it makes for a much more robust and reliable system. Any shop performing this level of work is likely to be experienced with this minor detail as it's a very common occurrence with other M16 extractors used for M700 actions.

338 Lapua Magnum Bolts:

The factory M700 bolts for this cartridge come with the M16 extractor installed as standard equipment. Historically, this has made converting this bolt style to a conventional magnum using the .532" case rim diameter near impossible. Recently, we set out to solve this problem and are happy to announce that it is now an option.

We Also Recommend