NOTE: Gunsmithing Services are invasive and will most often (directly with tooling or indirectly with work holding) damage existing surface finishes on parts such as receivers. LRI offers a full menu of finish options for your components, please ensure you have also added an appropriate finish option to your cart if applicable.

Finish Options

Cerakote (most popular)Parkerize Carbon Steel Action

Parkerize Carbon Steel Bolt

Glass Bead Stainless

GUNSMITHING SERVICES: Dual ejectors for M700's with AR15/M16 Extractors

Problem Statement:

Ejection with a factory bolt M700 fitted with an AR15/M16 extractor has always been plagued with an annoying problem. The issue is the ejection angle of the case body as it pivots on the extractor claw and attempts to leave the loading port of the action.

The factory ejector's clock position combined with the altered position of the claw causes the case to exit with a high trajectory that approaches 1 o'clock. (viewed as a RH shooter perspective behind the rifle) When combined with modern optics using large external "tree stump" windage turrets, it creates a very frustrating problem where the cartridge case contacts the scope turret and back flips right back into the loading port.

Some aftermarket bolts solve this by moving the ejector position to 9 o'clock. This restores the case to a near horizontal ejection angle. Unfortunately, this isn't a viable option for a factory bolt.

The Solution:

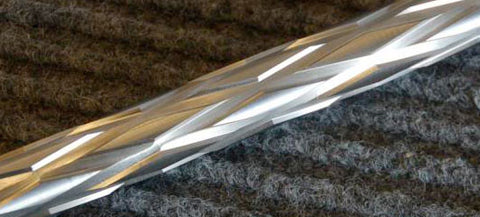

What LRI has done is add an additional ejector. We mirror it “north of the equator” on the bolt face. Doing so restores the ejection angle so that cases will again clear the turrets. The net result is a reliably extracting rifle that will "punt" the case low enough to clear the optics. Trimming the spring length on ejector pins is the last step, reducing the "blast radius" of spent cases. - This is quite helpful for "gamer gun" events where limited time is allocated for brass recovery.

Photo is shown with M16 extractor bushing also installed to the nose of the bolt face.

LRI has application-specific workholding and dedicated equipment for this service. When combined with our commitment to exploiting modern machining potential, it results in predictable outcomes with very fast delivery schedules. Hours and days rather than weeks and months are what we strive for.

This listing is for a service and the installation of new small parts. You must send us your bolt for this service. You are strongly advised to send us your barreled action to ensure proper fitment. Remington 700 actions rely on a counterbored breech ring that may require alteration for the extractor to function correctly.

Please also note that additional shipping rates may apply when returning barreled actions/firearms to clients.

Note* This service IS for BOTH RH and LH bolts.

We Also Recommend