GUNSMITHING SERVICES: STRIKER PIN BUSHING: M7, M700, M70(PF AND CRF), ACCURACY INTERNATIONAL, BERGARA, HOWA 1500, & RUGER RPR

A relatively frequent complaint with M700 and Accuracy International actions (and others) are cratered primers with factory made ammunition. The root cause of this is from excessive clearance between the striker and the hole through the bolt face. When fired, the primer cup flows into the void and indicates excessive pressure.

This glitch in the design is further confirmed when inspecting the radius transition around the circumference of the primer. If it has not been hammered flat, it's unlikely that the ammunition is exceeding pressure limits. Additional confirmation of this can be observed from the absence of an ejector mark/swipe on the face of the brass and case webs that have not grown excessively*.

*a "tick" at the top of the bolt's rotation out of battery is a tell tale sign of case web growth due to excessive pressure.

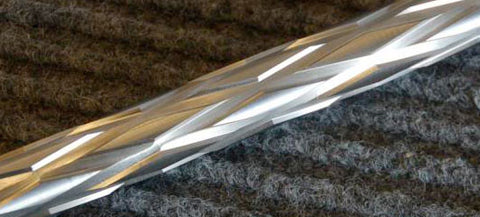

Machining the bolt and installing a bushing around the striker pin to tighten the tolerance is the answer to solving the issue.

Our bushing installation process is performed using a 2017 Haas 4 axis VF2 cnc machining center fitted with Renishaw probing and a Hardinge HLV Ultra Precision Tool Room Lathe. We also manufacture our own in house heat treated insert to serve as the bushing for installation into the bolt head.

It is important to note that part of this procedure involves a cleanup pass on the face of the bolt. This will alter the headspace dimension of the rifle slightly. With the recent implementation of our new milling center and probing, we can now control this tolerance quite well.

Expect your headspace to grow by .0005"-.0015" when working with a "healthy" bolt that is free of fire check damage or long term use.

A half to one and a half thousandths may seem like anything but control of a tolerance. One has to know that bolt faces (from the factory) often fluctuate. They are not always flat. Removing "just enough" may blend the machine work, but leave traces of the inclusions from manufacturing. We debated whether or not to leave this in the interest of preserving as much material as possible. In the end it was decided it better to clean the surface completely.

Factory ammo has never been affected adversely. With guns running reloads its advised that you simply back the sizer die out ever so slightly to make up the difference. A 14 thread sizer die has a pitch of .0714". It won't take much rotation to add an extra .0005-.0015 worth of headspace.

Because of this, it is encouraged that you have this service performed PRIOR to installing a new barrel.

The striker is then turned down from .075" to .0625" resulting in a smaller impact crater on the primer. Striker protrusion from the bolt face is also inspected and set to run within a tolerance range of .055" +0/-.003".

In addition to solving the cause of the problem, we are often approached about restoring a bolt face that has become "fire checked" by escaping gasses around the primer cup/pierced primers. Fire Checking is erosion of the bolt face. The fundamental cause is much like a cutting torch on a gas welder. The heat, velocity, and pressure of escaping gasses literally eats away at the face of the bolt.

We have a restoration process that enjoys a high degree of success. We cannot promise to restore every bolt to "as new" condition, but we will certainly do our best. This level of service is certain to alter the headspace of the rifle. If your gun is experiencing this problem, it would be best to wait until the barrel is shot out and due for replacement. This keeps the cost down as restoring headspace on a job like this is invasive/expensive.

We Also Recommend