GUNSMITHING SERVICES: 3D Surface Machined Inletting

Traditional gunsmithing dictates that a true custom rifle needs to have a pillar bedding job in order to wring the last bit of performance.

We agree with this in spirit as a well executed pillar bedding job is a thing of beauty. LRI has invested tremendously to deliver pillar bedding that is in a class all its own, delivering both the performance and fit/finish a true custom rifle calls for.

The demand for a middle ground alternative has always been on our minds. Because we begin with blank stocks void of any fitting, the costs are naturally higher. 3D Surface Machining effectively bridges this gap. Using the powerful resources of modern manufacturing, we are able to deliver the performance bedding offers along with almost all of the fit and finish requirements at considerable cost savings.

History:

In 2012 LRI was contracted to overhaul literally a "semi truck load" of precision guns for an international security and risk management firm. These rifles were primarily training guns however a few were designated for real world service abroad.

It was readily apparent that some radical measures were needed. The existing bedding had eroded to where it could be peeled from the alloy chassis. These rifles received the full menu of blueprinting and accurizing services offered by LRI.

It was here where LRI started the 3D machined inlet process. The work was experimental at the time. We built up a small sample of rifles and tested here, then shipped them back for evaluation. Final vetting of the work happened after the client took delivery.

The very next class had graduates posting the highest scores ever recorded for the DoS DDM (Department of State Defensive Designated Marksman) course by this company.

Process:

We begin with highly accurate 3D models of the actual receiver.

There are no generic routines used for this. In addition, barrel channel surfaces are generated using the actual barrel* on the rifle.

*Reputable barrel companies do a very good job of holding consistent contours. The issue at hand comes from fellow gunsmiths. No rule or standard exists for a shank length on a barrel. Its very important to know this dimension as it "drives the boat" for where the channel is ultimately positioned in the stock relative to the recoil lug or receiver face. Most will attempt to fit the barrel to the stock, however when starting from scratch the door is wide open to interpretation in many applications. Because of this, LRI absolutely requires your barreled action if we are stocking a barreled action fitted by an outside shop.

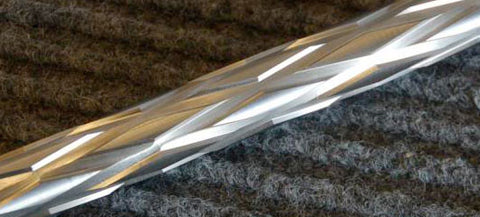

K&P Barrel Company 3B contour:

Surface machining is using a tool considerably smaller than the shape being created. With software, the tool is manipulated to "single point" the material into the desired geometry. This very same principle is how complex molds, aircraft turbine blades, and quite possibly, the case around your cell phone is made. The volume of information generated can be enormous in size and older legacy machinery often struggled to process the data. Thankfully, modern machining centers are built to handle this kind of "code" accurately and efficiently.

R/H Remington M700 Short Action, LRI M700 profile recoil lug, LRI Bolt handle, and K&P #4 contour barrel channel:

Our process retains the use of stainless steel pillars made in house. These differ slightly from our pillars used for bedding because here no resin flows between the stock and action.

LRI bedding pillar on left, Surface machining pillar on right:

The pillar is 100% in contact with the stock. To ensure proper contact we machine the pillar as part of the inlet simultaneously. Retention is further ensured by threading the OD of the pillar body and the guard screw bores in the stock.

Shown is a Manners T5-A right off the machine and being prepped for finishing:

Shown is a completed stock. Defiance SA Deviant Hunter fitted with a Proof Research Carbon wrapped barrel. Stock is finished in an in house varation of Kryptec camo. All LRI finishes are hand laid stencils and painted in Cerakote.

Performance:

Proof is in the pudding. Below is a 3 shot group fired at 200 yards by Matthew Krans, Owner of Longway Brass in Yankton SD. It was shot on 7.31.2018 with one of our full builds done on a surface inletted Manner's Composite T5-A rifle stocks. Cartridge is 22-250 Remington.

Notes:

This is a service. LRI is well stocked with popular models from Manner's Composite Stocks. We do not carry all of them however. Delivery schedules directly correlate to availability and inventory.

Our exclusive "status tracker" updates the work as we progress the job. You can expect routine updates via email as part of this service.

This service includes inletting the bottom side of the stock for your choice of bottom metal. All other services/options such as tactical rails or ULTACH installation are extra.

The options detail the current inventory of programming for this service. Other action designs can be added and we encourage clients to consider this. Modeling an action is a detail oriented process. Please allow for an additional 4 weeks when we have to model a specific action design not already offered.

We Also Recommend