GUNSMITHING SERVICES: Barrel Fluting

Notes regarding barrel fluting:

We always REMOVE the barrel from the receiver/action as a standard practice for our barrel fluting services.

*IF your barreled action uses a tombstone-type recoil lug that is NOT integral to the receiver, include the stock when sending us your parts.

*This is CRITICAL if your recoil lug and/or barreled action has been bedded.

- Barrel fluting is a machining process highly dependent on well-executed work holding. We have a well-vetted process for ensuring a visually clean appearance in our finished work. Please note that IF your barrel is coated, blued, blasted, or "finished" in any way on the outside, it WILL need to be refinished. There is no way to avoid this. LRI will not accept or be subject to any liability for this service. Please consider this before retaining us for the service.

- Barrel fluting is largely cosmetic. Because of this, we ask for some artistic freedom regarding the flute count and depth. Sometimes it's beneficial to alter toolpaths a bit in the interest of appearance. This is one of the cases in machine work where "if it looks right, it is right."

- The prices quoted for our barrel fluting services are for bolt action rifles and AR-15s where the barrel is attached to the receiver by threads or a barrel extension.

- The full range of possible attachment methods is outside of our scope to completely anticipate as the variances are almost infinite. LRI reserves the right to apply additional tooling costs when the application requires it. As always, you will be notified before any work begins. If you elect to proceed, you will be billed upon completion. Special tooling starts at $125 and up.

LRI offers fluting in 8 variations. Many of these have 2 different tooling styles available.

- "High Helix" (Pattern A or B)

- "Standard Helix" (Pattern A or B)

- "Straight" (Pattern A or B)

- "Interrupted"

- "Diamond"

- "Wrought Iron"

- "Murder Hornet"

- "Pattern X"

Flute tooling styles offered by LRI:

Pattern "A" and Pattern "B":

Pattern "A" is a faceted shape resembling the splines on a car's axle or PTO shaft on a tractor. If electing to have your barrel Ceracoted and want the flutes to be a different color, this is the pattern to go with because the faceted sides create a well-defined edge at the beginning and end of the feature. This allows us to mask the barrel with very clean lines.

Pattern "A" with 2x color Ceracote option:

Pattern "B" is a more conventional radial profile typical on most fluted barrels. The photos below highlight the differences.

Pattern "A": Pattern "B":

Pattern "A" High Helix:

Pattern "A" straight:

"Interrupted."

"Wrought Iron."

Machined to emulate decorative ironwork.

"Murder Hornet."

We recreate the barrel's cylindrical contour on the floor of the hexagonal pocket. This is a notable difference from many competitors who use a simpler 2-axis toolpath.

"Gain Twist."

A unique service we are proud to offer is gain twist fluting. This is where the machined helical features become progressively more aggressive down the length of the barrel cylinder.

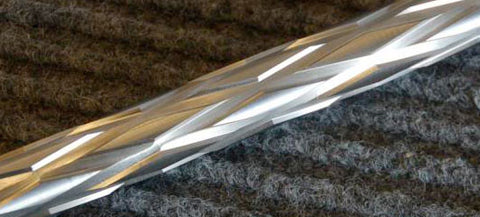

Pattern "X."

The response we've had with this pattern is nothing short of astounding. The barrel shown had a full POUND of material removed from it. Finished, it weighed within 3 ounces of a Proof Research Sendero contoured carbon barrel finished at 16". This barrel is 20" and has an extra inch of large diameter cylinder ahead of the recoil lug.

We now approach the weight savings of carbon-wrapped barrels and are confident that heat dissipation exceeds because it is all one material with a significant increase in surface area. We've performed this service to thousands of barrels using both the single point and button rifling methods of manufacturing. It's been demonstrated over and over again that our process has no detrimental effect on accuracy.

We Also Recommend